As we peer through our binoculars, we often take for granted the intricate details and advanced technologies that come together to enhance our viewing experience. One such technology that plays a crucial role in optimizing the performance of binoculars is lens coatings. These coatings, often invisible to the naked eye, can significantly impact the quality and clarity of the image we see.

Understanding binocular lens coatings is important and in this discussion, we will explore the fascinating world of binocular lens coatings, offering insights into their different types, their effects on light transmission, and the benefits they bring to our observations. Prepare to embark on a journey that will uncover the secrets behind the seemingly ordinary lenses of our binoculars.

Contents

- 1 Key Takeaways

- 2 What Happens When Light Travels Through Glass?

- 3 Understanding Binocular Lens Coatings

- 4 What are the Different Types of Binocular Lens Coatings?

- 5 Impact Of Coating On Lens Reflection

- 6 What are Different Coatings For Prisms?

- 7 How Do Mirror and Phase-Correction Coatings on Binocular Prisms Work?

- 8 What are the Benefits of Binoculars Lens Coatings?

- 9 Conclusion

- 10 References

- 11 Frequently Asked Questions

- 11.1 How Do Binocular Lens Coatings Affect Image Clarity and Brightness?

- 11.2 Can Binocular Lens Coatings Improve Color Reproduction and Contrast?

- 11.3 Are There Any Special Care Instructions for Binoculars With Lens Coatings?

- 11.4 Do Binocular Lens Coatings Affect the Overall Weight and Size of the Binoculars?

- 11.5 Can Binocular Lens Coatings Reduce Eye Strain and Fatigue During Extended Use?

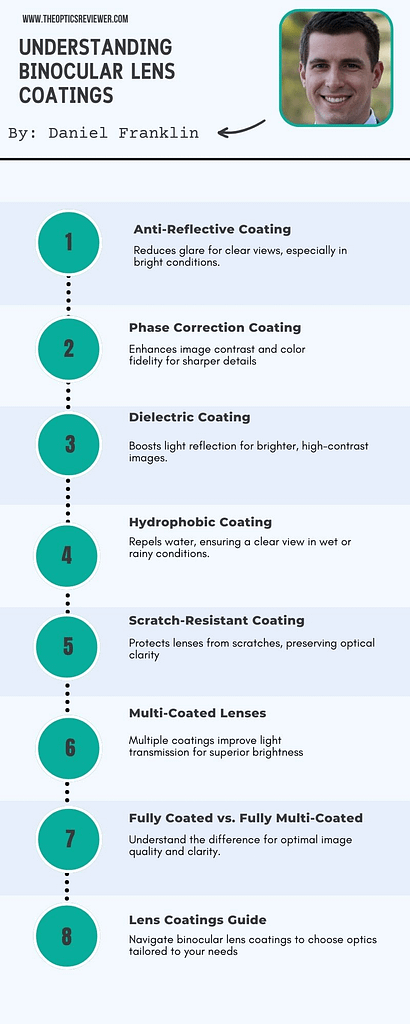

Key Takeaways

- Binocular lens coatings optimize performance by improving image quality, clarity, and contrast.

- They minimize reflections, glare, and optical aberrations, resulting in a clearer and sharper image.

- Coatings increase light transmission, making binoculars more effective in low-light conditions.

- Different types of coatings, such as anti-reflective, scratch-resistant, and water-repellent, provide additional benefits like reducing eye strain, protecting against damage, and maintaining clear vision in various weather conditions.

What Happens When Light Travels Through Glass?

When light travels through glass, it encounters molecules and atoms that cause absorption and reflection, resulting in a loss of intensity and the potential for disturbances such as reflections, Gaussian blur, reduced image contrast, and diffuse haze. Glass, although appearing transparent to the human eye, is not completely transparent to a beam of light. The incident light must navigate through the molecules and atoms present in the glass, leading to partial absorption and reflection.

During the transition from one medium to another, part of the incident light intensity is lost. As the light passes through multiple glass surfaces, the reflections increase, causing scattered light. These reflections, together with the useful light, can create light spots and reflections that disrupt the image seen through the glass. Additionally, the repeated reflections contribute to Gaussian blur, reducing the sharpness and clarity of the image. Furthermore, the contrast of the image is degraded due to the combination of scattered and useful light, resulting in a less defined visual perception.

To mitigate these disturbances, anti-reflective coatings are applied to the glass surfaces. These coatings minimize light reflection and maximize light transmission, reducing the absorption and scattering of light. By minimizing reflections and improving light transmission, anti-reflective coatings help to eliminate light spots, Gaussian blur, and diffuse haze, ensuring a clearer and sharper image with enhanced contrast.

Understanding Binocular Lens Coatings

When choosing binoculars, it’s crucial to understand the significance of lens coatings. These coatings play a vital role in light transmission, image clarity, and overall viewing experience. Lens coatings are applied to the glass surfaces of binocular lenses to reduce reflection, improve contrast, and enhance color fidelity. They are typically made of thin layers of chemical compounds that are applied through vacuum deposition processes.

The primary types of lens coatings include fully coated, multi-coated, and fully multi-coated. Fully coated binoculars have single-layer coatings on at least one glass surface, usually the objective lens. While they provide some improvement in light transmission, they are often basic and may not offer optimal performance in low-light conditions. Multi-coated binoculars feature multiple layers of coatings on one or more lens surfaces, offering better light transmission and image quality compared to fully coated models.

Fully multi-coated binoculars are considered the highest quality because they have multiple layers of coatings on all air-to-glass surfaces. This maximizes light transmission and minimizes reflection, resulting in crisp, clear images with enhanced contrast and color fidelity. Fully multi-coated binoculars are ideal for serious birdwatchers, nature enthusiasts, and astronomy hobbyists who demand optimal performance in various lighting conditions.

For example, if you compare a fully coated binocular to a fully multi-coated one in low-light conditions, you may notice that the fully multi-coated model provides brighter, sharper images with better contrast and color accuracy due to its advanced coatings. This illustrates how lens coatings can significantly impact the quality of your viewing experience with binoculars.

What are the Different Types of Binocular Lens Coatings?

When it comes to binocular lens coatings, there are several types to consider. Anti-reflective coatings help to reduce glare and increase light transmission, resulting in clearer images. Scratch-resistant coatings protect the lens surface from damage, while water-repellent coatings prevent water droplets from obstructing the view. Additionally, multi-coatings and fully multi-coated optics provide enhanced image quality by minimizing reflections and maximizing light transmission.

Anti-Reflective Coatings

Anti-reflective coatings on binocular lenses are a crucial component in reducing unwanted reflections and improving image quality. These coatings, also known as anti-glare coatings, are applied using advanced lens coating technology to enhance the optical performance of binoculars.

The advantages of anti-reflective coatings are numerous. Firstly, they minimize reflections caused by light bouncing off the lens surfaces, resulting in increased light transmission and brighter images. Secondly, they eliminate glare, especially in bright conditions, allowing for better visibility and less eye strain. Additionally, anti-reflective coatings improve contrast and color fidelity, enhancing the overall image quality.

The application process of lens coatings involves depositing multiple thin layers of special materials onto the lens surface. These layers are designed to reduce reflections and increase light transmission. Furthermore, some anti-reflective coatings also include UV protection coatings, providing additional protection against harmful ultraviolet rays.

Scratch-Resistant Coatings

Scratch-resistant coatings are essential components of binocular lenses that provide durability and protect against scratches and abrasions. These coatings enhance the lens longevity and maintain the optical clarity of the binoculars. Here are four key points to understand about scratch-resistant coatings:

- Scratch resistance: The primary purpose of these coatings is to prevent scratches on the lens surface, which can impact the overall image quality and clarity.

- Durability: Scratch-resistant coatings increase the durability of the binocular lenses, making them more resistant to everyday wear and tear.

- Lens protection: These coatings act as a protective barrier, guarding the lenses against dust, dirt, and other contaminants that can cause scratches.

- Coating effectiveness: The effectiveness of these coatings is determined by their hardness and adhesion to the lens surface, ensuring long-lasting protection.

Investing in binoculars with scratch-resistant coatings is crucial to maintain the lens’s performance and extend its lifespan.

Water-Repellent Coatings

Water-repellent coatings play a crucial role in enhancing the performance and functionality of binocular lenses. These hydrophobic coatings are designed to repel water, preventing droplets from forming on the lens surface. By minimizing water contact, these coatings improve lens durability and maintain optical performance.

One of the primary benefits of water-repellent coatings is their ability to prevent water droplets from obstructing the field of view. This feature ensures that users can maintain clear vision, even in wet or rainy conditions. Additionally, these coatings make it easier to clean the lenses, as water and dirt are less likely to adhere to the surface.

Water-repellent coatings also contribute to lens clarity by reducing the formation of water spots and smudges. This allows users to enjoy a clear and unobstructed view, enhancing the overall viewing experience. By incorporating hydrophobic coatings, manufacturers ensure that binoculars are equipped with lenses that are both durable and easy to maintain, providing users with optimal performance in various weather conditions.

Multi-Coated Optics

Multi-coatings, specifically fully multi-coated optics, are a vital component of binocular lens coatings, contributing to improved optical performance and image clarity. These advanced optical coatings utilize the latest lens coating technology to enhance light transmission, reduce reflections, and minimize flare and ghosting. The benefits of multi-coatings in binoculars include:

- Increased light transmission: Multi-coatings improve the efficiency of light transmission through the lens, allowing more light to reach your eyes and resulting in brighter and clearer images.

- Reduced reflections: By reducing internal and external reflections, multi-coatings help to eliminate unwanted glare and improve contrast, enabling you to see fine details even in challenging lighting conditions.

- Enhanced color accuracy: The precise application of multi-coatings helps to preserve the true colors of the observed scene, providing a more realistic and immersive viewing experience.

- Improved durability: Multi-coatings are designed to be highly durable, protecting the lens surface from scratches, abrasions, and environmental factors, ensuring long-lasting performance.

Fully Multi-Coated Optics

Fully Multi-Coated Optics are a crucial element in achieving optimal light transmission and image quality in binocular lens coatings. These coatings are applied to all glass surfaces to minimize lens reflection and maximize light transmission. With fully multi-coated optics, multiple layers of anti-reflective coatings are applied to each lens surface, resulting in a high level of light transmission of up to 90-95%.

This significantly reduces lens reflection and improves image clarity, brightness, and contrast. Prism coatings and mirror coatings are also included in fully multi-coated optics to further enhance light transmission and image quality. By effectively reducing lens reflection and maximizing light transmission, fully multi-coated optics play a vital role in delivering sharp and vibrant images through binoculars.

Prism Coatings

Prism coatings in binocular lens coatings encompass various types that contribute to the enhancement of light transmission and image quality. These coatings are designed to optimize the optical performance of binoculars by reducing light reflections and increasing brightness. Here are four important aspects of prism coatings:

- Anti-Reflective Coatings: These coatings minimize reflections on the prism surfaces, allowing more light to pass through and reducing glare for a clearer image.

- Phase Correction Coatings: These coatings correct the phase shift that occurs when light passes through prisms, resulting in improved color fidelity and image sharpness.

- Dielectric Coatings: These coatings enhance light transmission by utilizing multiple layers of dielectric materials, ensuring maximum brightness and contrast.

- Coating Durability: Prism coatings are designed to be highly durable, protecting the prism surfaces from scratches, abrasions, and other environmental factors.

Prism coatings are a crucial part of modern binoculars, utilizing advanced coating technology to enhance light transmission and optimize optical performance.

Impact Of Coating On Lens Reflection

Lens coatings are crucial in binoculars as they can significantly enhance the clarity, contrast, and brightness of the images seen through the lenses. Different types of lens coatings exist, each offering unique advantages. The table below compares three common types of lens coatings:

| Type of Lens Coating | Description | Benefits |

|---|---|---|

| Single-Coated | A single layer of coating applied to one lens surface | Reduces glare and improves light transmission |

| Multi-Coated | Multiple layers of coating applied to one or more lens surfaces | Further reduces glare, enhances color fidelity, and increases light transmission |

| Fully Multi-Coated | Multiple layers of coating applied to all lens surfaces | Maximizes light transmission, minimizes reflections, and provides superior image quality |

When choosing lens coatings, several factors should be considered, such as the intended use of the binoculars, budget, and personal preferences. Ultimately, the right lens coating will contribute to a clearer and more enjoyable viewing experience.

If interested lets read more about can you use binoculars with glasses.

What are Different Coatings For Prisms?

When it comes to prism coatings, there are two main types: mirror coatings and phase correction coatings. Mirror coatings are designed to reduce or eliminate reflections, improving image brightness and contrast. Phase correction coatings are specifically applied to correct phase shifts caused by the prisms, ensuring accurate color reproduction and image sharpness. These coatings play a crucial role in optimizing the performance of prisms in binoculars, enhancing the overall viewing experience for users.

If interested lets read more about are binoculars allowed at concerts.

Mirror Coatings

Mirror coatings play a crucial role in enhancing light transmission and, consequently, improving the brightness and contrast of binocular lenses. Advancements in mirror coating technology have led to significant improvements in binocular performance. Here are four key points to consider when comparing different types of mirror coatings:

- Mirror coatings are designed to improve light transmission, allowing more light to reach the observer’s eyes. This results in brighter and clearer images.

- The type and quality of mirror coatings can have a direct impact on image clarity. Higher quality coatings reduce the loss of light and minimize reflections, leading to sharper images.

- Different mirror coatings may have varying levels of durability and resistance to scratches, affecting the longevity and overall performance of the binoculars.

- It is important to consider the specific needs and preferences of the user when choosing mirror coatings, as different coatings may produce different visual effects.

Phase Correction Coatings

Phase correction coatings are specialized coatings applied to binocular prisms to correct for the optical phenomenon of phase-shifting, which can degrade image quality by reducing detail, contrast, and color accuracy. Unlike Porro prisms, roof prisms suffer from phase-shifting, causing the wavelengths passing through the prism to shift out of phase, resulting in a muddy image with less detail and contrast, as well as alterations in color perception.

If interested you can read more about are binoculars allowed on airplanes.

Phase correction coatings work by applying a thin film to the prism surfaces, which helps to realign the wavelengths and eliminate phase-shifting. This mechanism effectively restores the image quality, enhancing detail, contrast, and color accuracy. The importance of phase correction coatings in binoculars cannot be overstated, as they play a crucial role in ensuring high-quality, sharp, and vibrant images for the user.

| Phase Correction Coatings |

|---|

| Correct phase-shifting |

| Enhance image quality |

| Realignment of wavelengths |

| Improve detail, contrast, and color accuracy |

| Essential for high-quality binoculars |

How Do Mirror and Phase-Correction Coatings on Binocular Prisms Work?

Understanding the functionality of mirror and phase-correction coatings on binocular prisms is essential in comprehending how these coatings contribute to the optical performance and accuracy of binoculars. Mirror coatings are applied to the prism surfaces to enhance reflectivity and light transmission.

They work by reflecting light off the surface of the prism, allowing more light to reach the observer’s eyes. This results in brighter and clearer images, especially in low-light conditions. Mirror coatings also reduce light loss caused by internal reflections within the prism, further improving image quality.

On the other hand, phase-correction coatings are designed to correct a phenomenon known as phase shift, which can occur when light passes through a prism. Phase shift can cause image degradation and reduced clarity, particularly in high-end binoculars. Phase correction coatings, typically made of a dielectric material, correct for this phase shift by equalizing the path length of light passing through the prism. This ensures that the two light paths remain in phase, resulting in improved clarity and color fidelity.

Both mirror and phase-correction coatings are applied using advanced prism coating techniques, such as vacuum deposition. These techniques allow for precise and uniform coating application, ensuring consistent optical performance across the entire prism surface. The combination of mirror and phase-correction coatings significantly enhances the performance of binoculars, providing sharper, brighter, and more accurate images for the observer.

If interested you can read more about how far can you see with binoculars.

What are the Benefits of Binoculars Lens Coatings?

Lens coatings on binoculars offer a range of benefits that enhance optical performance and improve the overall viewing experience. These advantages are achieved through the use of advanced coating technologies that have been developed to meet the demands of modern binocular users. Here are four key benefits of binocular lens coatings:

- Improving performance: Lens coatings can significantly improve the performance of binoculars by increasing light transmission. This allows for brighter and clearer images, especially in low-light conditions.

- Enhancing image quality: Coatings help to reduce reflections and minimize the occurrence of optical aberrations such as chromatic aberration and lens flare. This results in sharper, more vibrant images with better color accuracy.

- Reducing glare: Glare can be a major issue when using binoculars, particularly when observing bright objects or in direct sunlight. Lens coatings help to reduce glare by minimizing the amount of light that is reflected off the lens surfaces.

- Increasing durability: Lens coatings also provide a protective barrier against scratches, abrasions, and other forms of damage. This helps to extend the lifespan of the binoculars and ensures that they continue to deliver optimal performance over time.

Conclusion

In conclusion, understanding binocular lens coatings is crucial for enhancing the performance and clarity of binoculars. Different types of coatings, such as anti-reflective coatings and prism coatings, play a significant role in reducing unwanted reflections and improving light transmission.

Mirror and phase-correction coatings on binocular prisms further enhance image quality and brightness. By employing these coatings, binoculars provide users with a more immersive and enjoyable viewing experience, making distant objects feel closer and more relatable.

References

- https://link.springer.com/article/10.1007/BF00235723

- https://link.springer.com/article/10.1007/BF00233186

- https://link.springer.com/article/10.1007/BF00237700

- https://link.springer.com/article/10.1007/BF00248796

Frequently Asked Questions

How Do Binocular Lens Coatings Affect Image Clarity and Brightness?

Binocular lens coatings play a crucial role in enhancing image clarity and brightness. They improve low light performance, minimize glare, and optimize depth perception. Different types of coatings have varying impacts, and their long-term durability is an important consideration.

Can Binocular Lens Coatings Improve Color Reproduction and Contrast?

Binocular lens coatings have a significant impact on color accuracy and contrast, enhancing image quality. Advanced anti-reflective coatings reduce glare and improve sharpness, while specialized coatings optimize contrast and performance in low light conditions.

Are There Any Special Care Instructions for Binoculars With Lens Coatings?

When it comes to caring for binoculars with lens coatings, there are a few important considerations. Cleaning techniques should be gentle and use specialized lens cleaning solutions. Proper storage, utilizing recommended accessories, and avoiding common mistakes can help maintain the integrity of the coatings. Additionally, it is important to be aware of the impact of weather conditions on the binoculars.

Do Binocular Lens Coatings Affect the Overall Weight and Size of the Binoculars?

Binocular lens coatings can affect the overall weight and size of the binoculars. Different coatings have varying impacts on durability, longevity, light transmission, low light performance, and lens scratch resistance.

Can Binocular Lens Coatings Reduce Eye Strain and Fatigue During Extended Use?

Optimal positioning of binocular lens coatings can reduce eye strain and fatigue during extended use by providing blue light protection, enhancing lens coating durability, maintaining depth perception, and promoting long-term eye health.